Products

Full-floor hopper aeration system

View product

Cyclone air system

View product

Catwalks

View product

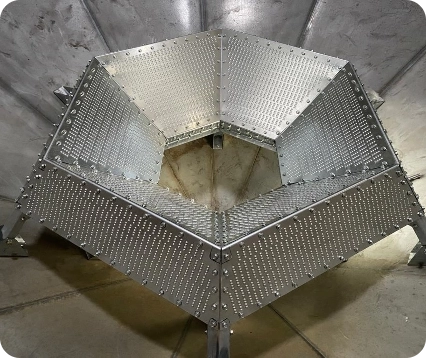

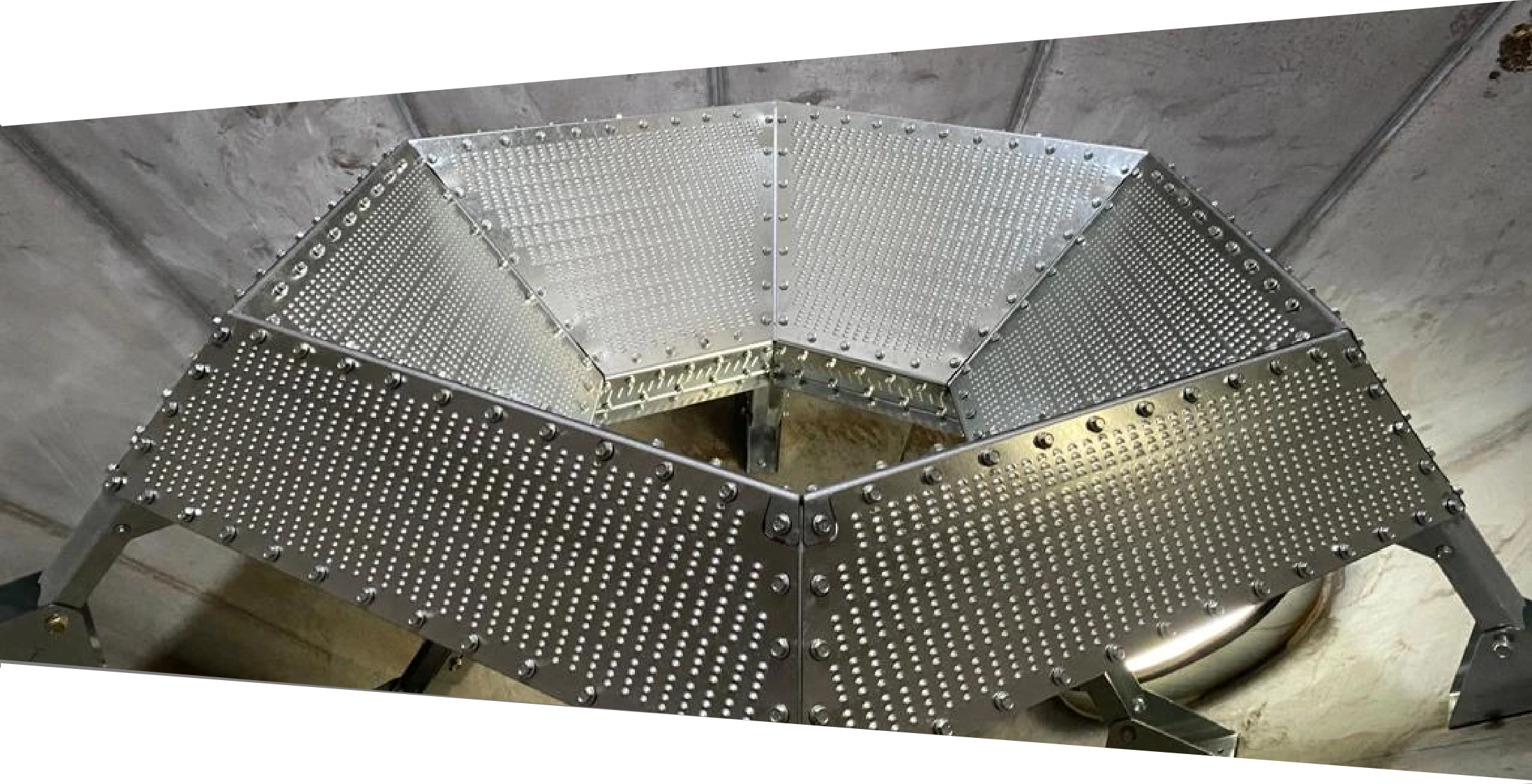

Full-floor hopper aeration system

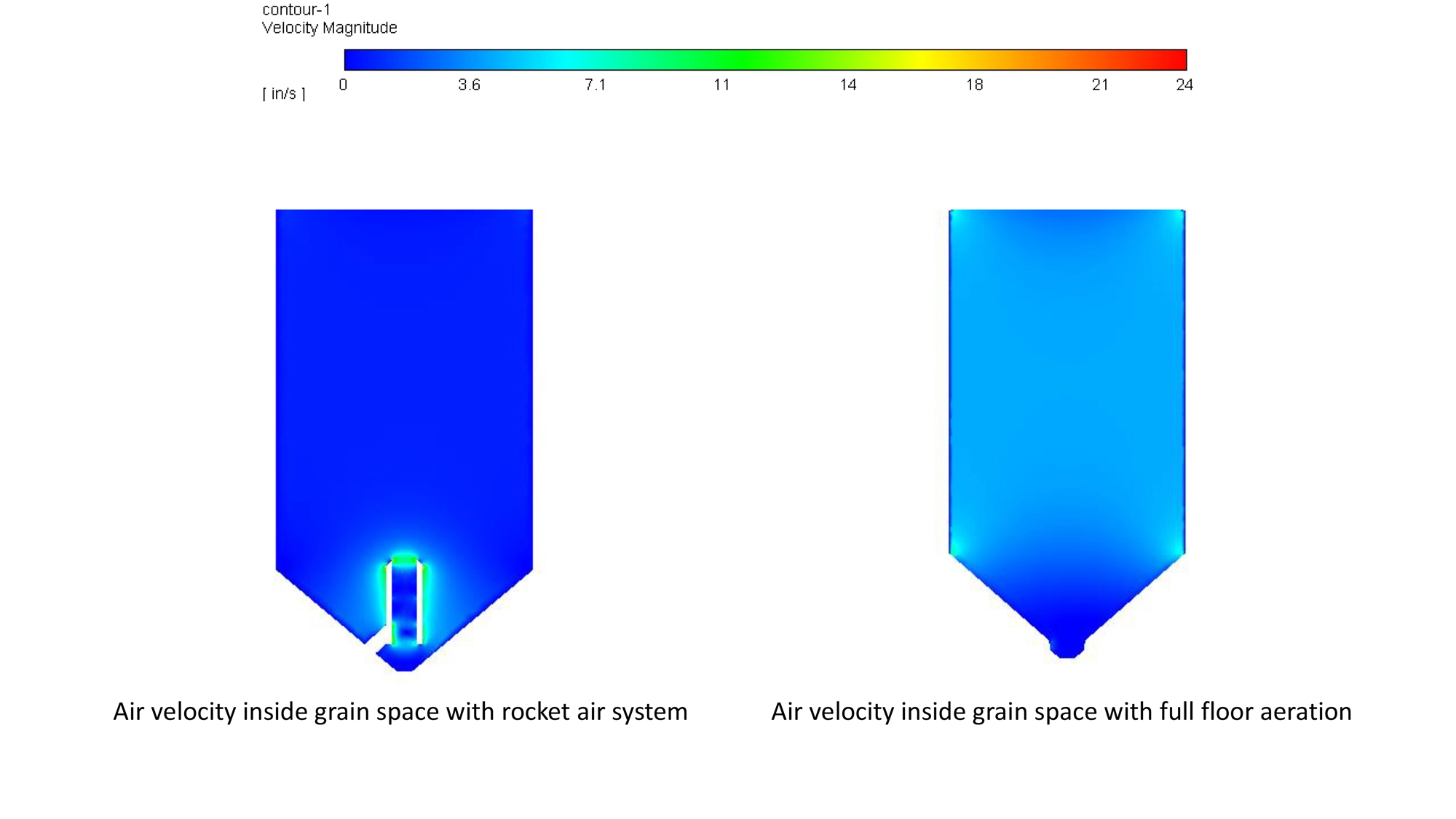

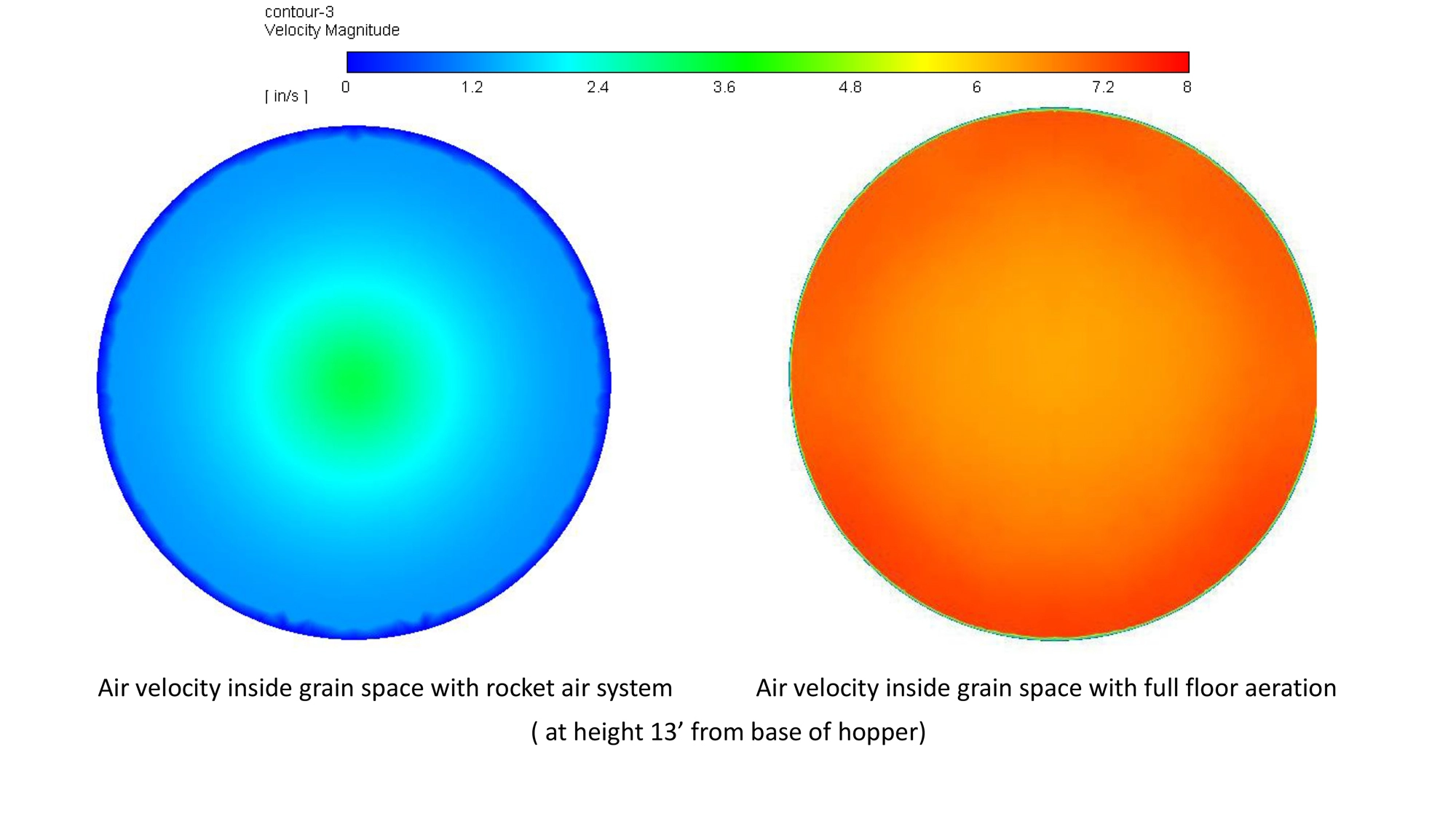

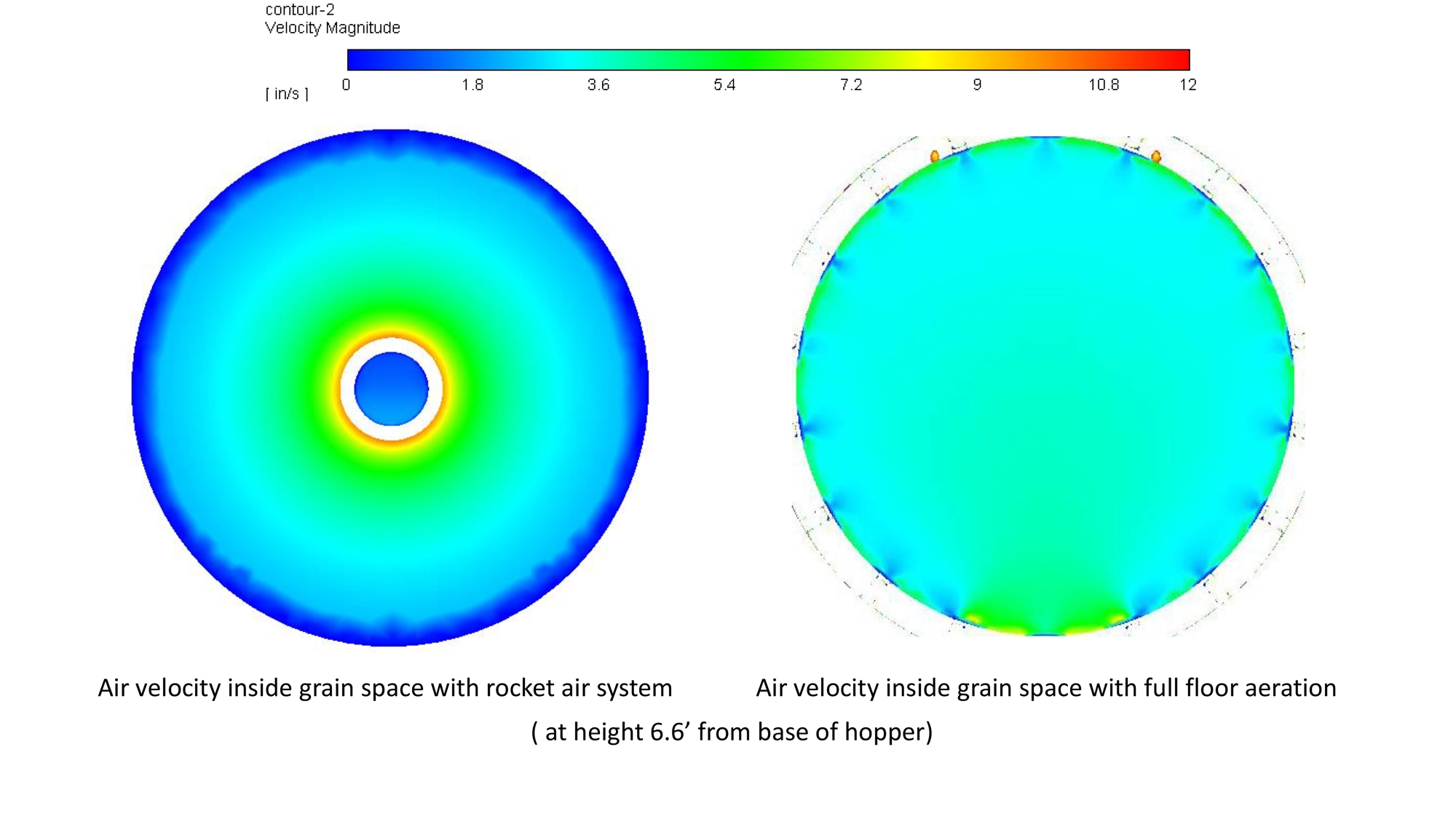

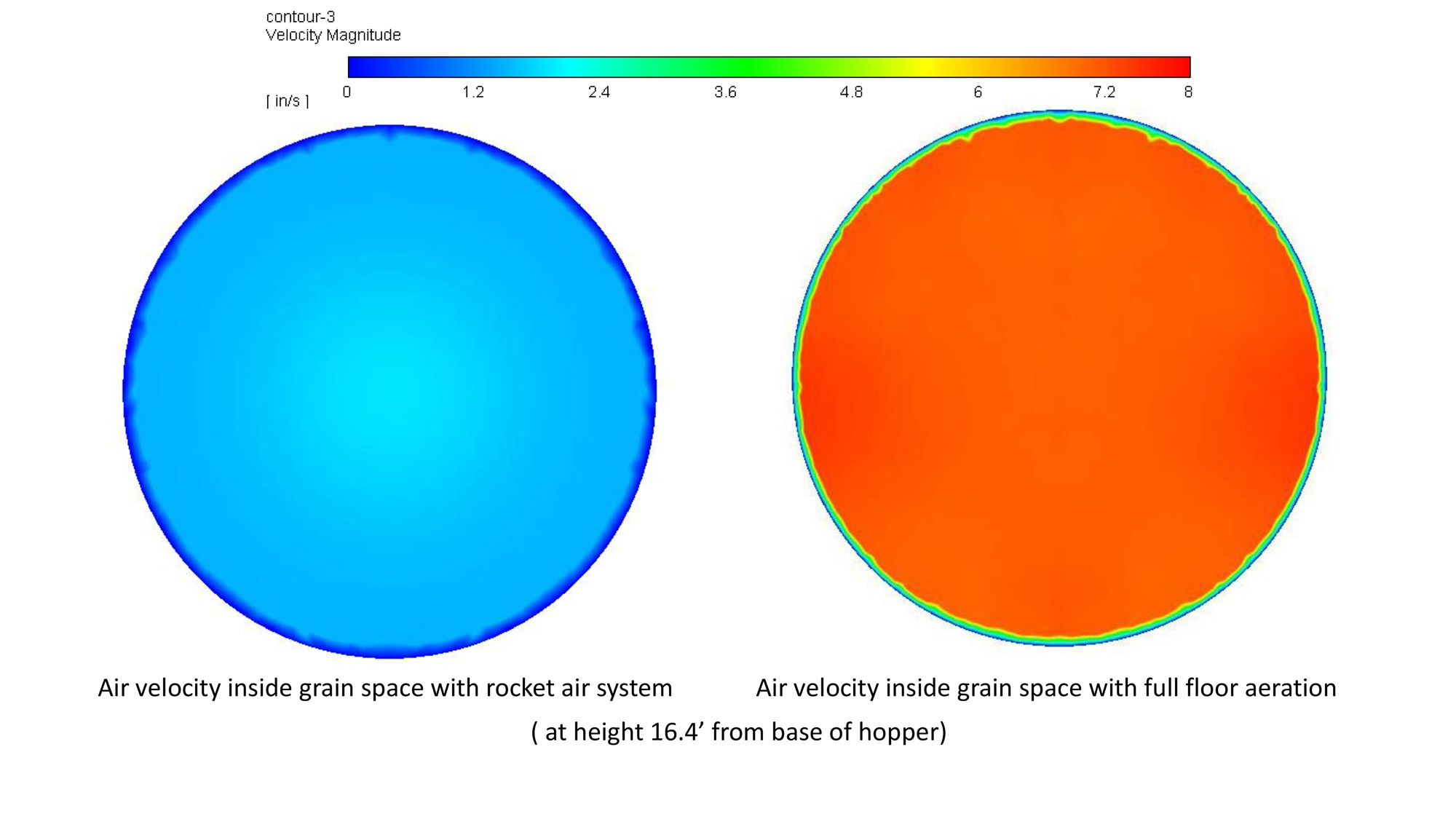

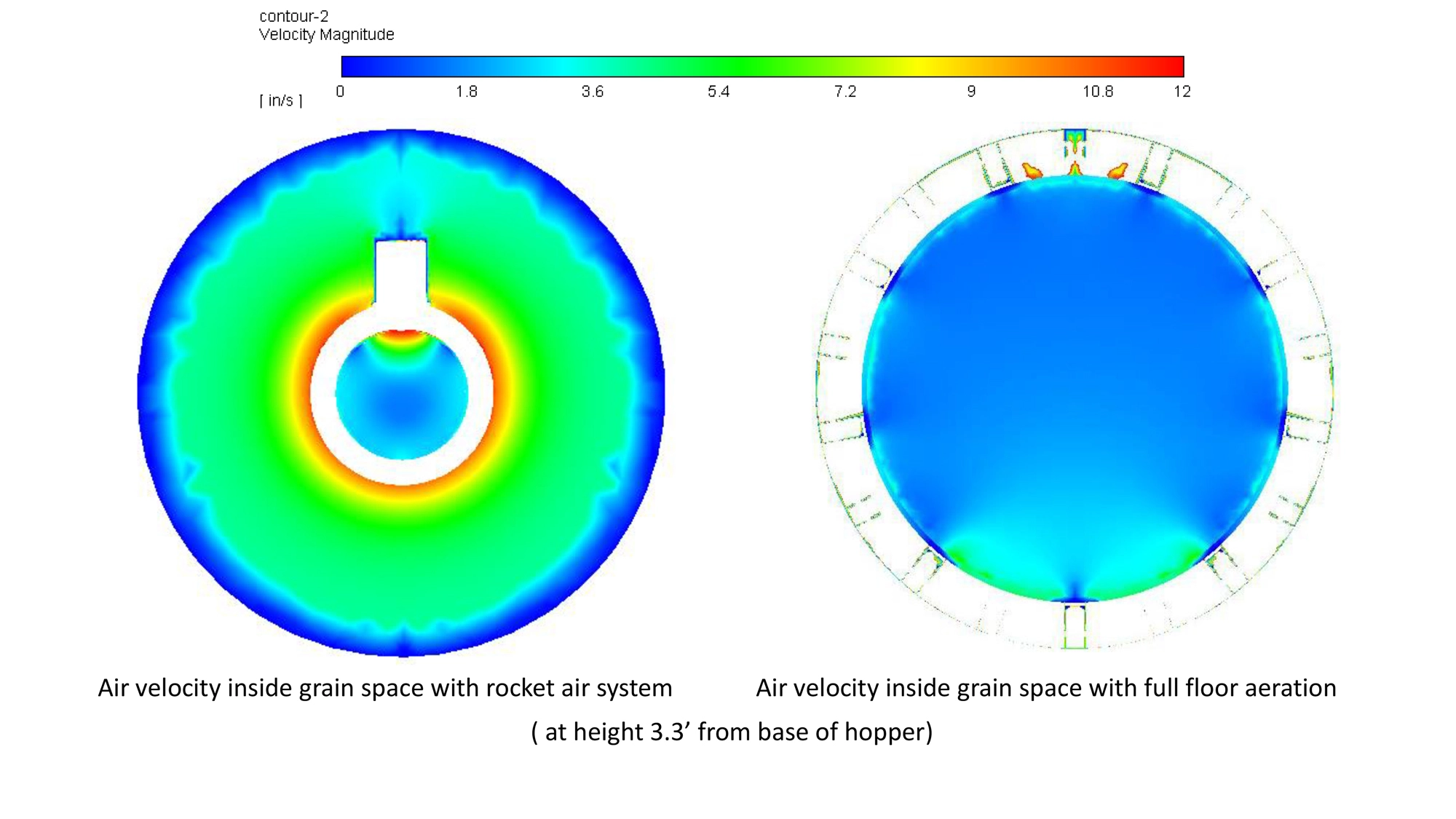

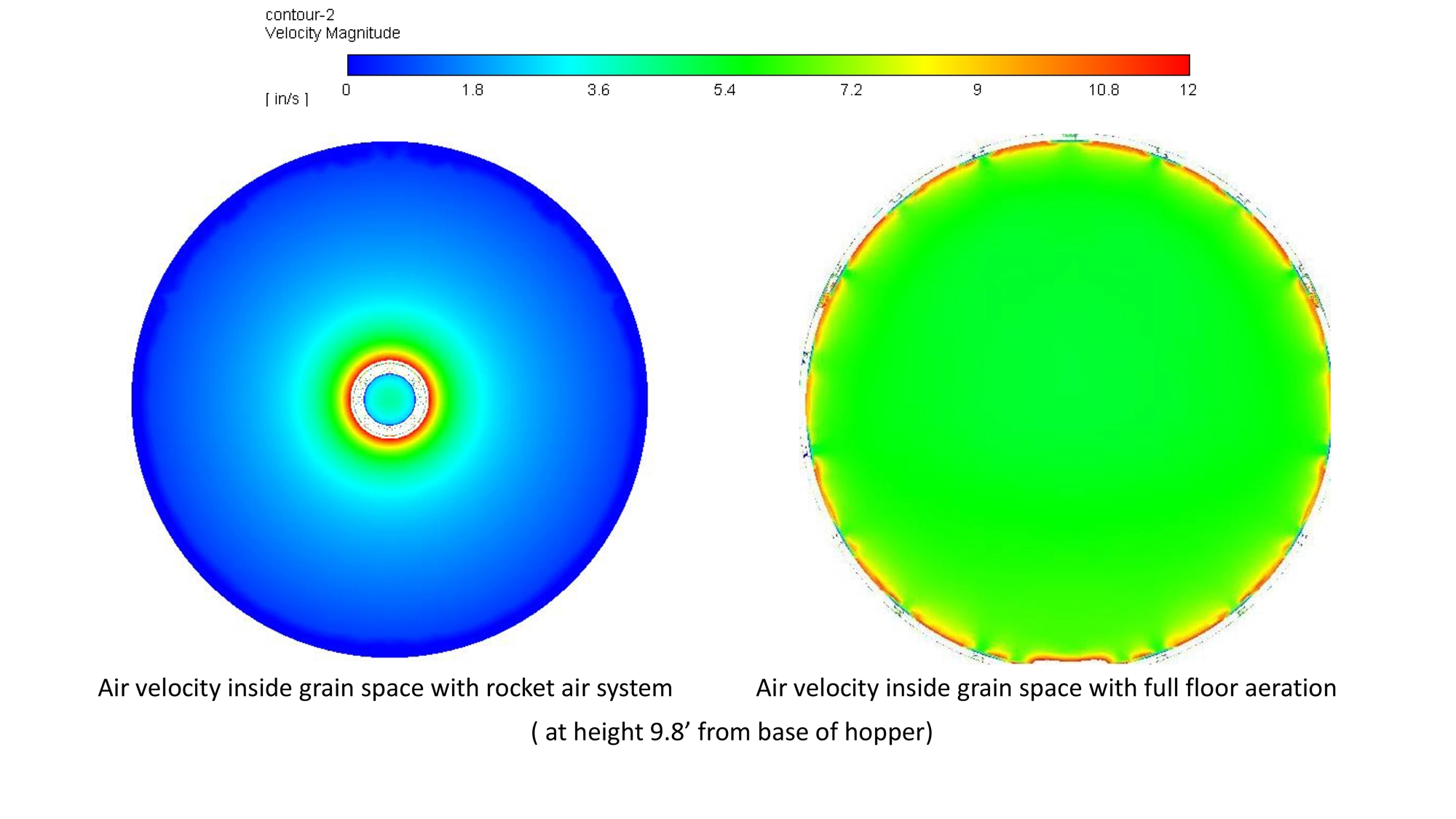

THIS SYSTEM INCLUDES A SECOND, PERFORATED FLOOR INSIDE THE HOPPER CONE. THE AIR IS THEN EQUALLY DISTRIBUTED BETWEEN THE HOPPER CONE AND PUSHED THROUGH THE PERFORATED FLOOR. AS A RESULT, GRAIN BINS DO NOT NEED TO BE FILLED TO THE TOP FOR OUR AERATION SYSTEM TO WORK. YOUR GRAIN WILL ALWAYS RECEIVE EVEN AIRFLOW. OUR AIRFLOW CHARTS ARE AVAILABLE ON OUR WEBSITE.

THE NORBIN FULL-FLOOR HOPPER AERATION SYSTEM USES A SPECIAL PERFORATION DESIGN THAT ALLOWS FOR EXCELLENT AIRFLOW AND WORKS WITH ALL SIZES OF GRAIN AND SEEDS. ALL GRAIN INSIDE YOUR BIN IS BEING AERATED BY THE WHOLE HOPPER CONE. THIS IS POSSIBLE WITH OUR NEW PATENT-PENDING AERATION SYSTEM.

OUR BOLT-TOGETHER HOPPER AND AERATION SYSTEMS ARE BEING BUILT USING 100% GALVANIZED STEEL THAT WILL LAST FOR GENERATIONS.

WITH OUR 40-DEGREE HOPPER CONE, THE AERATION SYSTEM IS DESIGNED SO THAT NO GRAIN REMAINS IN YOUR BIN. THIS ALSO ALLOWS THE DUST IN THE AIR CAVITY TO SPILL OUT WHEN YOUR BIN IS EMPTIED.

OUR BOLT-TOGETHER DESIGN ALLOWS US TO SHIP ON A STANDARD FLAT-DECK TRAILER, THEREBY REMOVING THE COSTS AND RESTRICTIONS ASSOCIATED WITH OVER-DIMENSIONAL SHIPMENTS. THIS ALSO ALLOWS US TO DELIVER OUR PRODUCTS TO MANY REMOTE AND HARD TO ACCESS SITES.

Cyclone air system

THIS NEW CYCLONE AIR SYSTEM IS A UNIQUE DESIGN STRATEGICALLY FOCUSING THE AERATION TO ELIMINATE WET POCKETS IN YOUR GRAIN BIN. THIS SYSTEM CREATES A CIRCLE OF LOUVRED PERFORATED MATERIAL INSIDE YOUR HOPPER BIN LIFTED OFF THE FLOOR ENOUGH FOR GRAIN TO FLOW UNDERNEATH BUT NOT TOO HIGH TO AERATE TO THE BOTTOM OF THE CONE. AS A RESULT, GRAIN BINS DO NOT NEED TO BE FILLED TO THE TOP FOR OUR AERATION SYSTEM TO WORK.

THE NORBIN CYCLONE AERATION SYSTEM USES A SPECIAL PERFORATION DESIGN THAT ALLOWS FOR EXCELLENT AIRFLOW AND WORKS WITH ALL SIZES OF GRAIN AND SEEDS. ALL GRAIN INSIDE YOUR BIN IS BEING AERATED. OUR CYCLONE AERATION SYSTEM IS BUILT USING 100% GALVANIZED STEEL THAT WILL LAST FOR GENERATIONS.

THIS AERATION SYSTEM IS DESIGNED SO THAT NO GRAIN REMAINS IN YOUR BIN AFTER DISCHARGING. IF ASSEMBLED AT OUR FACILITIES, OUR BOLT-TOGETHER DESIGN ALLOWS US TO SHIP ON A STANDARD FLAT- DECK TRAILER. IT CAN ALSO BE SHIPPED IN A STANDARD-SIZE BOX TO BE INSTALLED INTO ANY EXISTING HOPPER BIN, ALL PARTS WILL FIT THROUGH ANY STANDARD-SIZE MANHOLE/DOOR. THIS AIR SYSTEM CAN BE SHIPPED ANYWHERE VIA LTL.

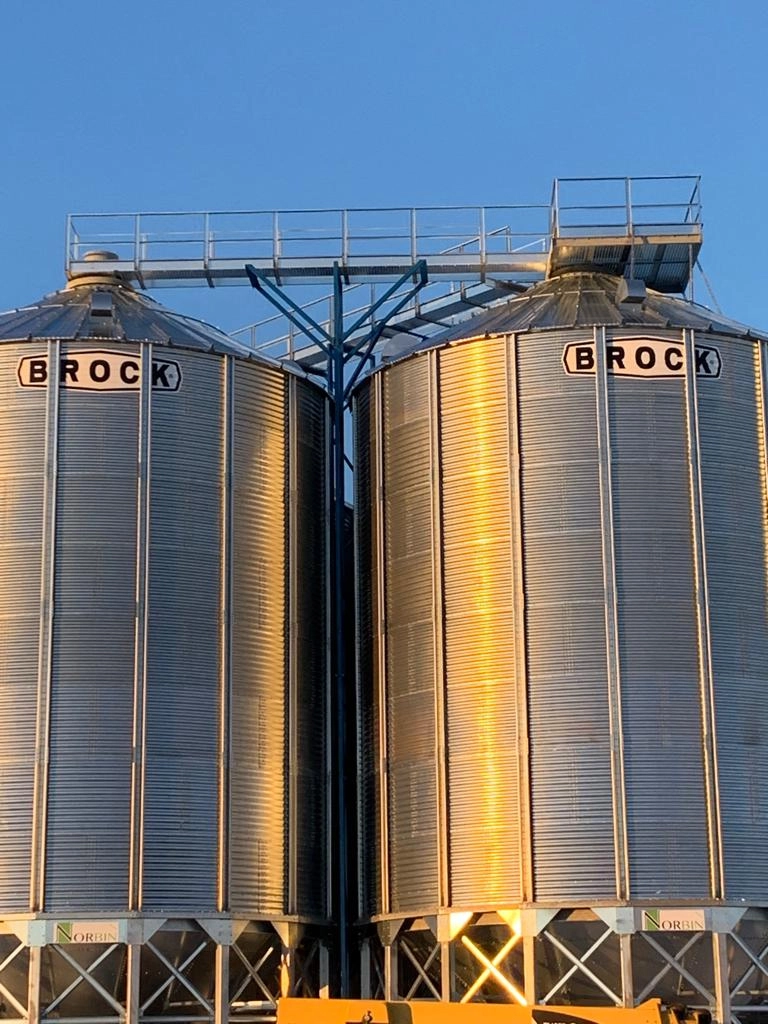

Catwalks

IF YOUR GRAIN STORAGE AND HANDLING SITE IS UNIQUE, WE CAN DESIGN AND ENGINEER FOR YOUR SPECIFIC SET- UP. OUR STANDARD SPAN IS 50 FEET AND CAN BE CUSTOMIZED FOR YOUR SITE. OUR TOWERS ARE DESIGNED AND BUILT TO YOUR SPECIFIC NEEDS. NORBIN CATWALK AND TOWER SYSTEM OFFERS STRUCTURAL SUPPORT, EASY ASSEMBLY, AND IS ENGINEERED FOR SAFETY AND DEPENDABILITY IN ALL WEATHER CONDITIONS.

OUR BOLT-TOGETHER CATWALK SYSTEMS ARE BUILT USING 100% GALVANIZED STEEL THAT WILL LAST FOR GENERATIONS. OUR CATWALKS PROVIDE OUTSTANDING OPTIONS THAT ALLOW LARGE-CAPACITY CONVEYORS TO SPAN LONG, OVERHEAD DISTANCES. WE OFFER A CUSTOMIZED SOLUTION FOR EVERY SITE AND CONDITION. OUR CATWALKS SUPPORT HIGH CAPACITY LOADS AND LARGE AREAS FOR MAINTENANCE AND INSPECTIONS. THEY ARE ENGINEERED AND PRECISELY MANUFACTURED TO THE HIGHEST STANDARDS TO GIVE YOU YEARS OF USE, MAINTENANCE FREE. OUR BOLT- TOGETHER DESIGN ALLOWS US TO SHIP ON STANDARD TRUCKS THEREBY REMOVING THE COSTS AND RESTRICTIONS ASSOCIATED WITH OVER-DIMENSIONAL SHIPMENTS. OUR FULLY BOLT TOGETHER ASSEMBLY REQUIRES MINIMAL OR NO WELDING FOR EASIER INSTALLATION. IT ALSO ALLOWS US TO EXPORT AND DELIVER OUR PRODUCTS TO MANY REMOTE AND HARD TO ACCESS SITES.